Plastic vs Wood Pallets: What's Best for Your Business?

In the dynamic landscape of the global commerce boom, pallets are unsung heroes that facilitate the seamless movement of goods. These flat structures are the foundation for efficient logistics, providing a stable base for transporting diverse commodities.

However, as businesses navigate plastic pallet choices in NZ, a significant debate emerges between the two primary contenders: plastic and wood.

Join us on this exploration as we unravel the nuances of the plastic vs. wood pallet debate and shed light on the factors influencing businesses' choices in their quest for optimal logistics solutions.

Environmental Impact

Plastic

While plastic pallets are known for their durability and reusability, their recyclability poses a significant concern. Plastic pallet disposal and recycling processes can contribute to environmental issues, as certain plastics are challenging to recycle efficiently. Consequently, accumulating non-recyclable plastic waste can result in long-term environmental consequences.

However, buying from an environmentally friendly company like Rotaform Plastics helps mitigate this issue. We design our durable plastic products to last up to 25 years, eliminating one-way packaging costs and providing substantial value to your supply chain. Our products are also recyclable, promoting responsible disposal at the end of their lifespan.

Wood

Wood pallets present a more environmentally friendly alternative as they come from renewable materials and are inherently sustainable. Their biodegradability and ability to be easily recycled or repurposed contribute to a lower ecological footprint.

Cost and Durability

Plastic

Although plastic pallets often incur higher upfront costs than their wooden counterparts, their durability and longevity offer a substantial return on investment. Plastic pallets boast resistance to moisture, pests, and decay, resulting in a prolonged lifespan and reduced replacement frequency.

Wood

Wood pallets typically entail lower initial costs, but their resilience over time hinges on proper maintenance, environmental exposure, and handling practices. The potential for splintering, warping, or decay can impact the longevity of wood pallets, necessitating a closer examination of the trade-off between upfront expenses and the enduring durability of the chosen material.

Hygiene and Safety

Plastic

Plastic pallets have emerged as advantageous in several industries when addressing the crucial aspects of hygiene and safety. The non-porous nature of plastic makes these pallets resistant to moisture absorption and impervious to bacterial growth, contributing significantly to maintaining high hygiene standards. Additionally, plastic pallets are inherently easy to clean and sanitise, crucial attributes for industries with stringent hygiene requirements, such as pharmaceuticals and food processing. Their consistent structure and smooth surfaces also reduce the risk of injury during handling.

Wood

Wood pallets require meticulous attention to cleanliness and adherence to safety standards. While wooden pallets are common, especially in shipping, they can be susceptible to absorbing liquids, potentially leading to contamination or bacteria growth.

Regular cleaning and adherence to safety protocols are paramount to ensure the hygiene and safety of goods transported on wood pallets.

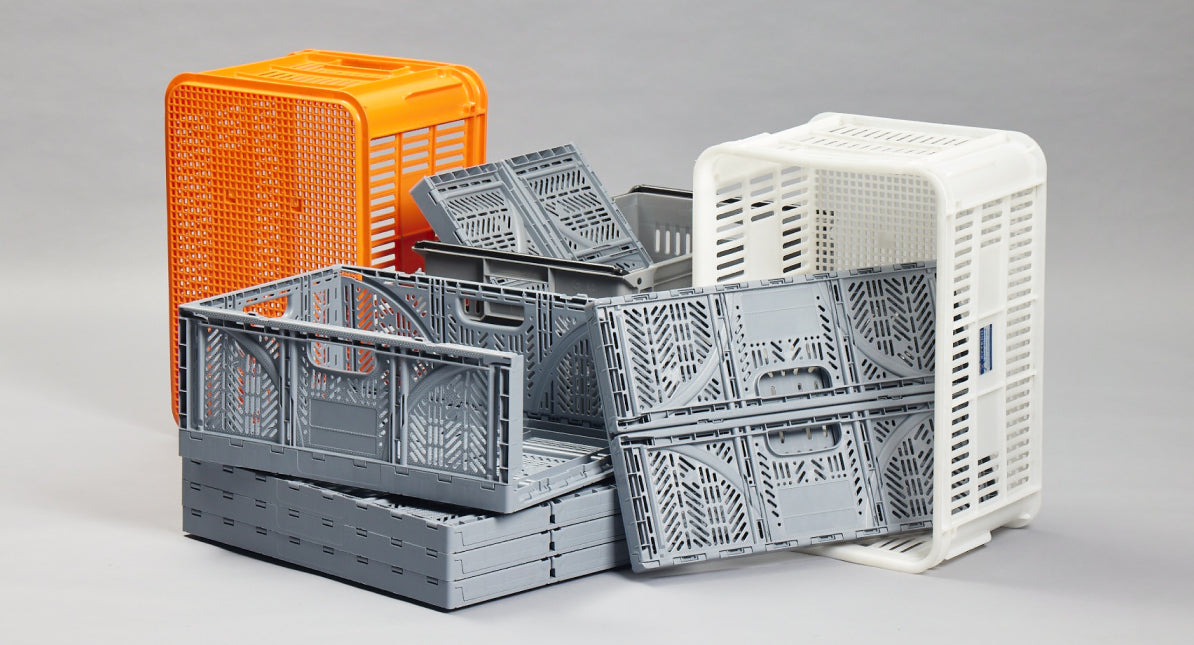

Customisation and Design

Plastic

Plastic pallets stand out for their inherent flexibility and extensive customisation options. These pallets can be moulded into various shapes and sizes to accommodate specific needs, making them adaptable to various industries. Their versatility allows for incorporating features such as reinforced edges, multiple entry points, and various load-bearing capacities.

Wood

Wood pallets feature a traditional design that has stood the test of time. While they exude a timeless aesthetic and are suitable for many applications, they may pose potential limitations concerning customisation. Wood's natural constraints can restrict the degree to which these pallets can be tailored to unique specifications, potentially limiting their suitability for certain specialised purposes.

Industry Applications

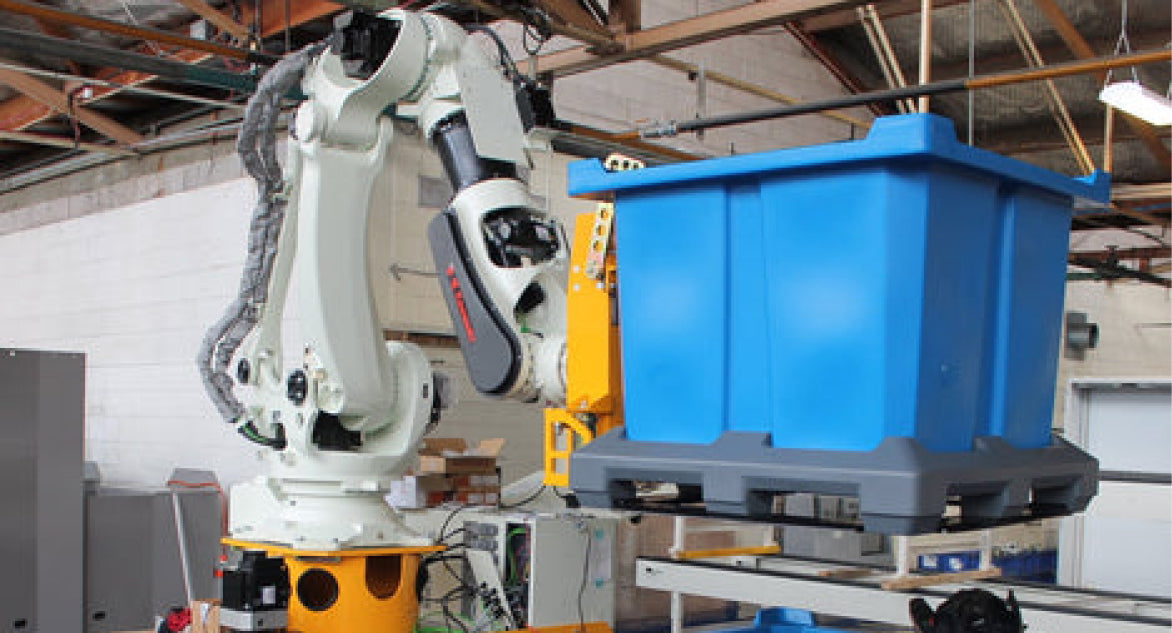

Plastic

Plastic pallets exhibit a remarkable suitability for specific industries, particularly in sectors where hygiene and cleanliness are paramount, such as food and pharmaceuticals. The non-porous nature of plastic prevents the absorption of liquids and contaminants, ensuring compliance with stringent industry regulations. Additionally, plastic pallets are resistant to moisture, mould, and pests, making them an ideal choice for sectors that demand strict adherence to hygiene standards.

Wood

Wood pallets, while possessing strengths rooted in their durability and cost-effectiveness, may encounter weaknesses across various sectors. In industries where sanitation is of utmost importance, the porous nature of wood poses challenges as it can absorb and retain moisture, potentially compromising the integrity of sensitive products.

Regulatory Compliance

Plastic

Given their resistance to chemicals and durability, plastic pallets are particularly suitable for industries complying with specific regulations, especially those governing the transport of hazardous materials.

Wood

As the World Trade Organisation mandates, the timber utilised in crafting wood pallets must meet International Standards for Phytosanitary Measures No. 15 (ISPM 15). Adherence to international shipping regulations and compliance with treatment standards for pest control prevents the transmission of diseases and insects that threaten the wellbeing of native forests.

Why Choose Plastic Pallets?

Unlike wood pallets, plastic pallets emerge as a standout solution, offering unparalleled durability, resistance to moisture, and compliance with stringent regulations. These qualities make them ideal for industries prioritising long-term efficiency and environmental responsibility.

For those seeking reliable material handling pallets, consider exploring the Rotaform Plastics range. Whether you're looking for standard export pallets or bespoke shipping solutions, you can shop for high-quality plastic pallets or customise unique solutions tailored to your needs. Invest in a company specialising in sustainable practices and reduce your global impact today!