Who uses rotaform?

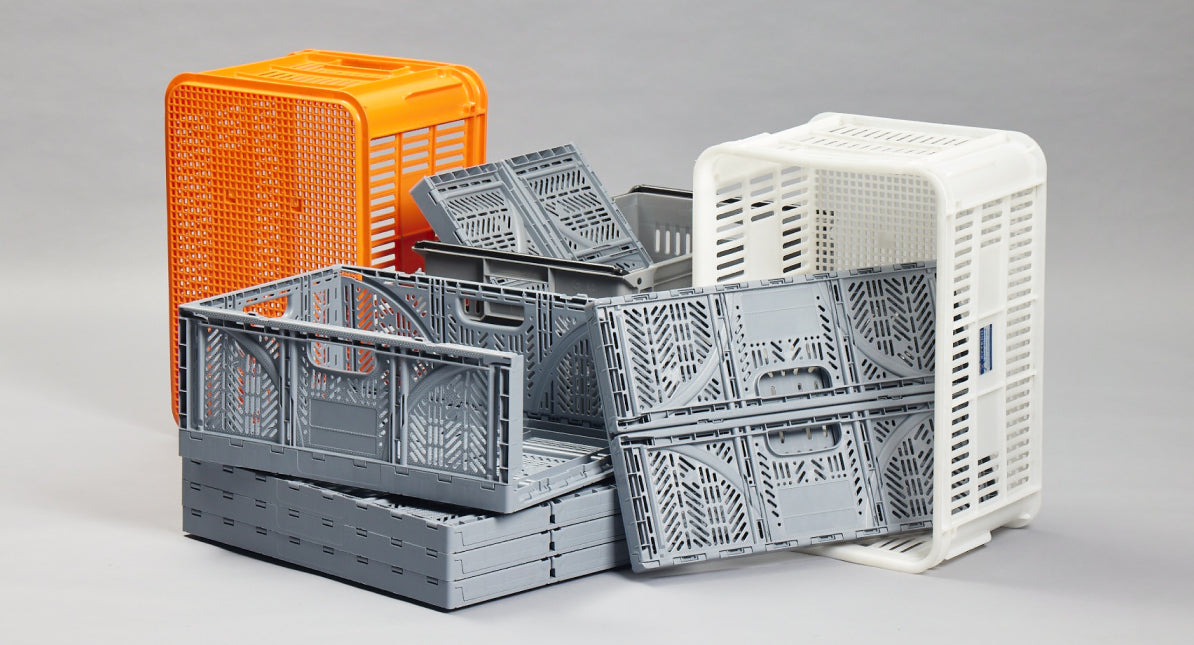

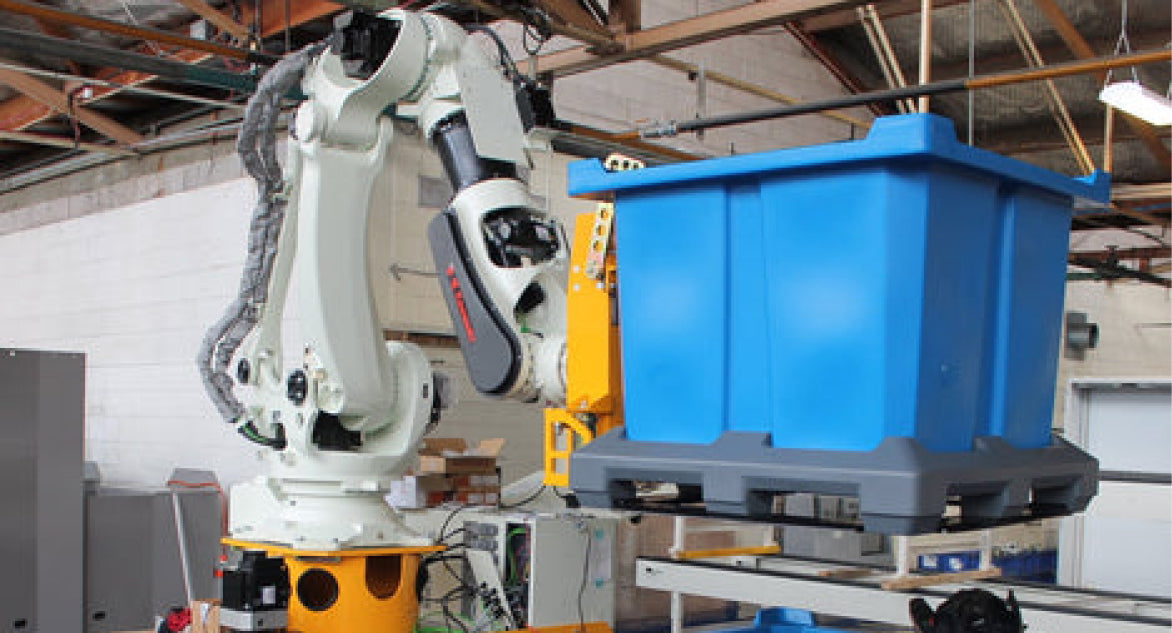

Rotaform helps businesses that need to improve and build new manufacturing processes for their organisation. By partnering with us, businesses have the freedom to design and source custom-moulded plastic containment solutions that optimise their supply chain and automation processes.

Our typical clients need high quality outcomes with minimum business risk as well as support and assistance with optimising their logistics channels. We work with smaller companies through to multi-nationals.

Why companies Choose rotaform

NZ based factories with a global manufacturing work

Depending on your product or project, it’s often more affordable to use a combination of local prototyping and service and international manufacturing. Our team of local experts will help you find the best designed solution while delivering the most affordable unit price across our local/global factory network.

Quality plastics built to last

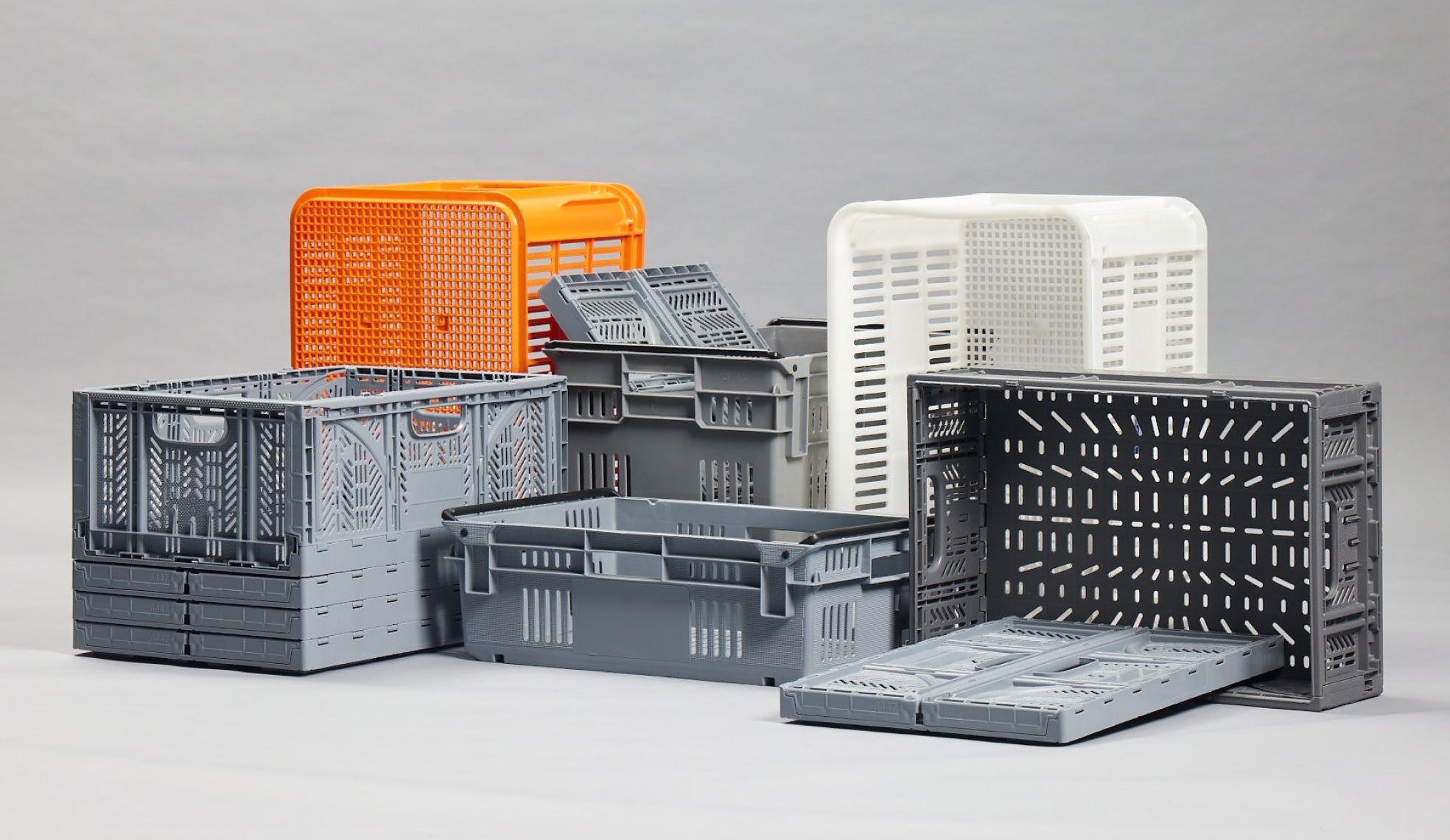

Rotaform products are designed to deliver time after time. Through our meticulous production process refined over 40 years, patented designs and high quality raw materials guarantee superior and longer lasting products.

Experienced manufacturers

We are the low-risk option for plastic products. What makes us different is that we’re not only importers, we’re plastic manufacturers with over 40 years of industry experience. We understand your specifications and we have no hesitation in helping you find innovative solutions that minimise overall business risk.

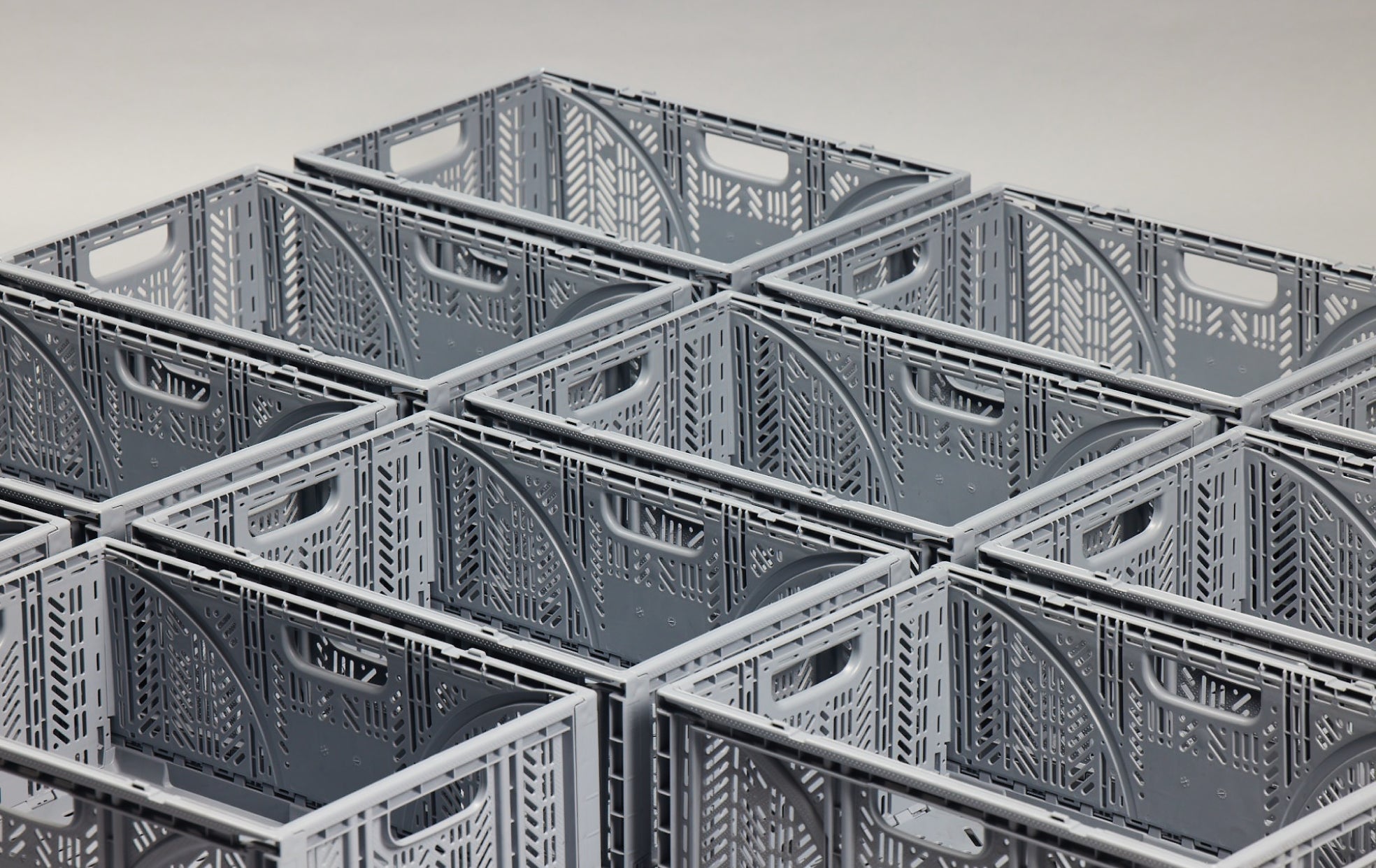

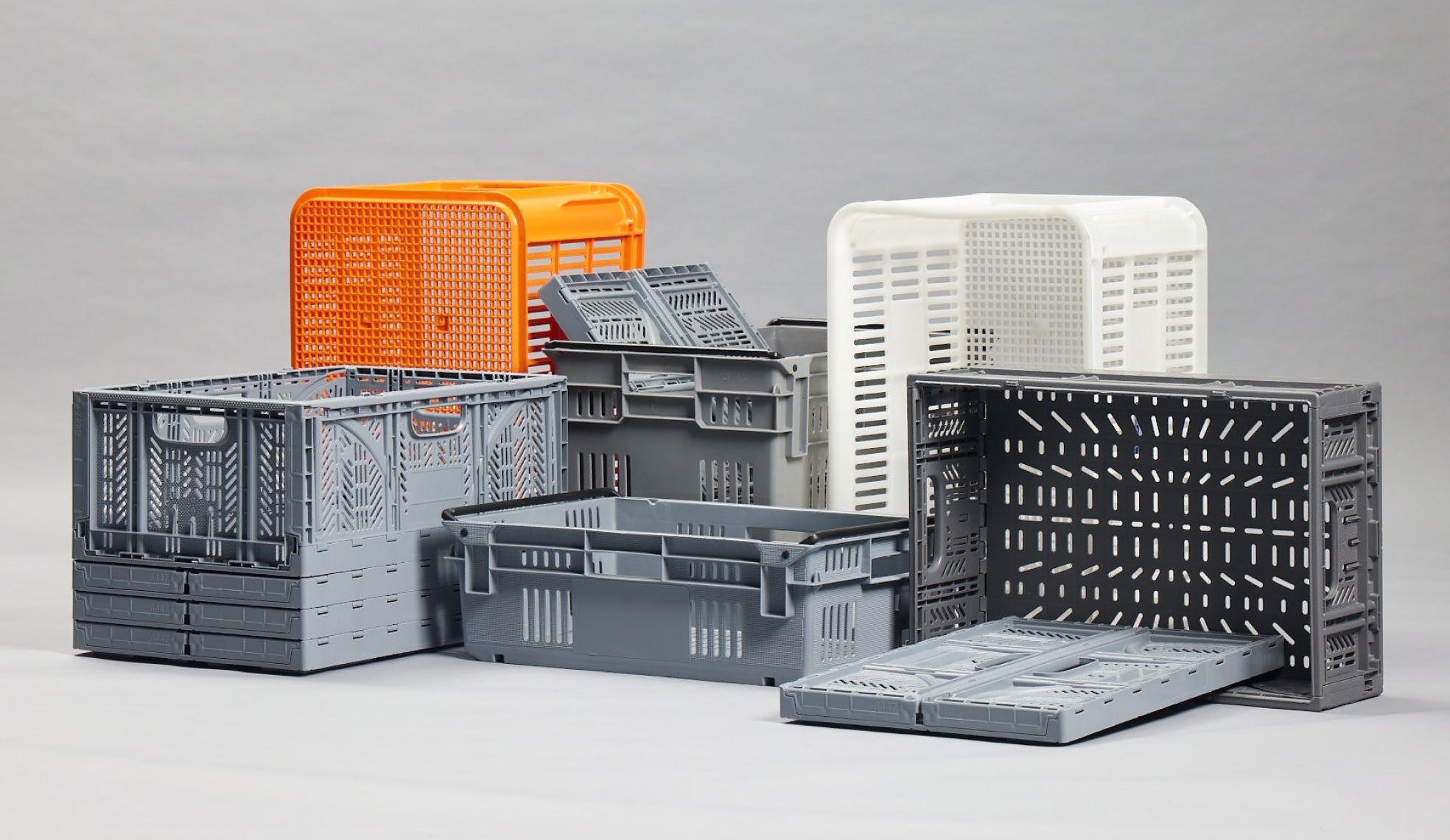

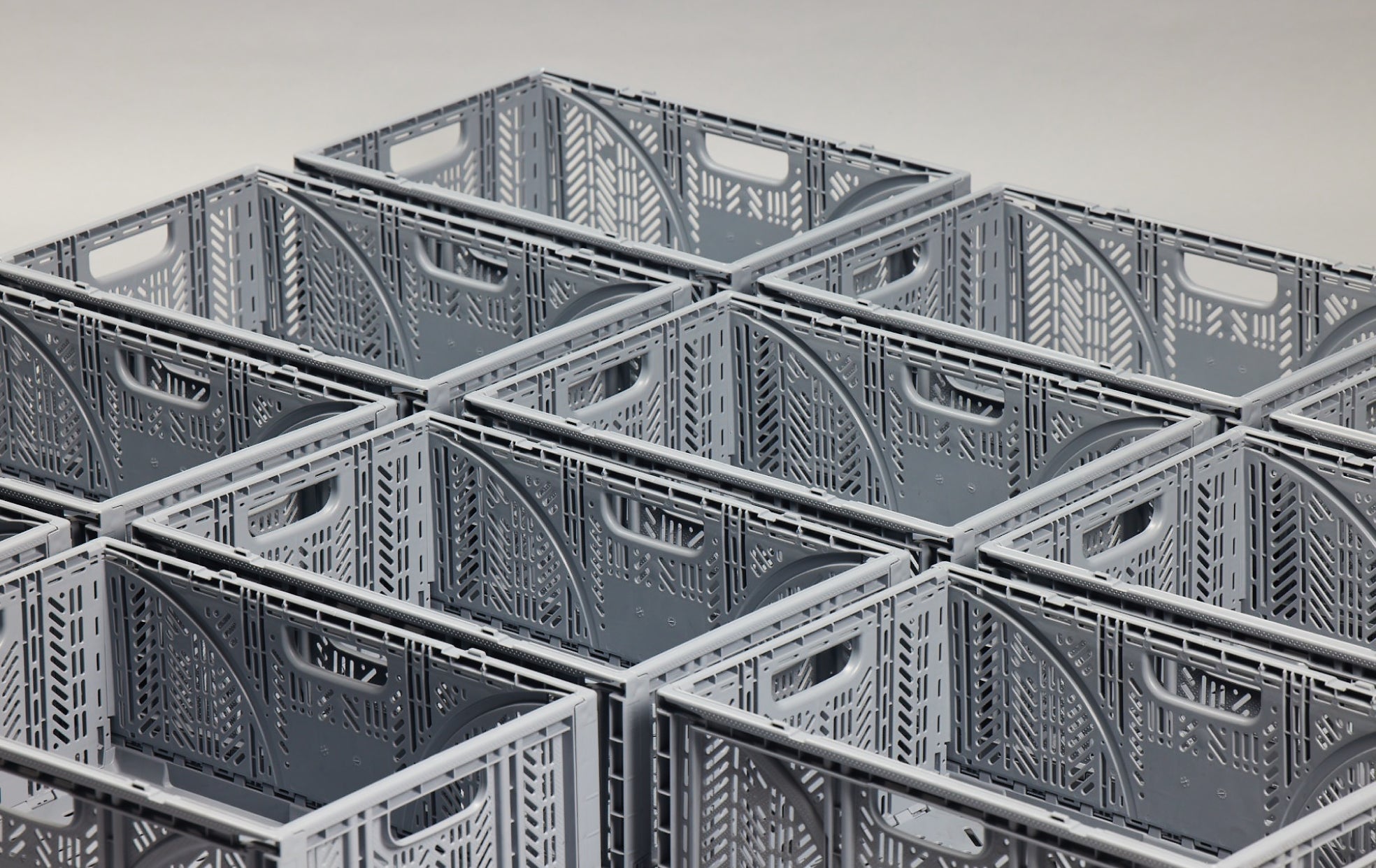

Extensive product range

With hundreds of products in stock and access to thousands more, we work closely with our trusted network of established suppliers and delivery partners to source or make virtually any product.

Bulk Pricing

Whether you’re looking to purchase 100,000+ units or a single bin, Rotaform wins on value. We have invested heavily in our facilities and award-winning design capability to guarantee high quality plastic products at a very affordable price. Our sourcing expertise removes any hidden costs and delivery delays. We work hard so you don’t have to.

Why companies Choose rotaform

NZ based factories with a global manufacturing work

Depending on your product or project, it’s often more affordable to use a combination of local prototyping and service and international manufacturing. Our team of local experts will help you find the best designed solution while delivering the most affordable unit price across our local/global factory network.

Quality plastics built to last

Rotaform products are designed to deliver time after time. Through our meticulous production process refined over 40 years, patented designs and high quality raw materials guarantee superior and longer lasting products.

Experienced manufacturers

We are the low-risk option for plastic products. What makes us different is that we’re not only importers, we’re plastic manufacturers with over 40 years of industry experience. We understand your specifications and we have no hesitation in helping you find innovative solutions that minimise overall business risk.

Extensive product range

With hundreds of products in stock and access to thousands more, we work closely with our trusted network of established suppliers and delivery partners to source or make virtually any product.

Bulk Pricing

Whether you’re looking to purchase 100,000+ units or a single bin, Rotaform wins on value. We have invested heavily in our facilities and award-winning design capability to guarantee high quality plastic products at a very affordable price. Our sourcing expertise removes any hidden costs and delivery delays. We work hard so you don’t have to.

We are here to help

For general inquiries or questions regarding sales or press, please leave your contact information below and we will get back to you as soon as possible.

Phone

NZ: 09 275 2144

Global: +64 9275 2144

Head Office

59 Montgomery Rd, Mangere,

Auckland 2022

Message Us

Our purchase support team typically respond within 90 minutes, during business hours.

Our Services

As a team of award winning designers and manufacturing experts we take pride in our ability to consistently deliver robust designs and with the attention to detail that critical creating a perfect product.